Optical sorter for carrots

Software with artificial intelligence

Highly precise sorting, calibration and weighing

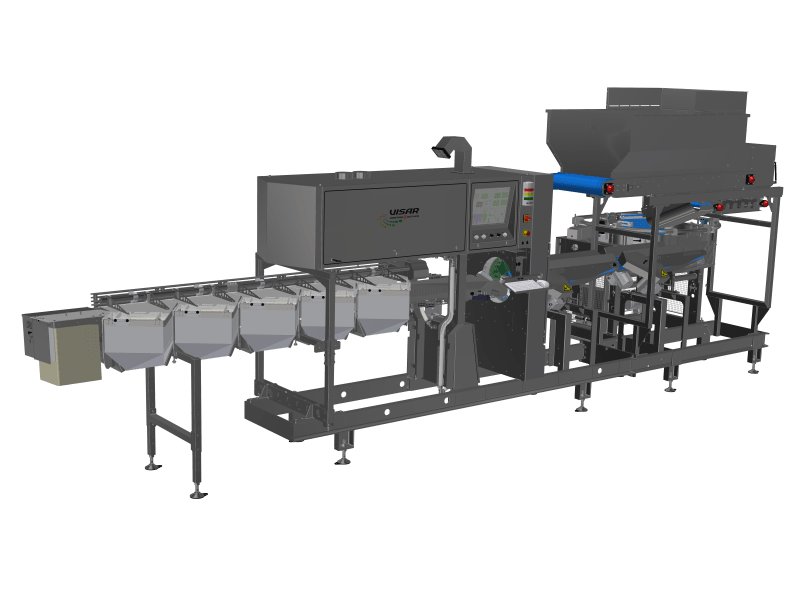

Sortop Carrots

Rotative feeder

> high productivity!

Worldwide unique, intelligent software

Highly precise sorting, calibration & weighing

(diameter, length and weight)

Up to 16 outputs, customized solutions

360 ° HD analysis, unsurpassed sorting quality

Maximum profitability and efficiency

The machine for carrots

High capacity and maximum profitability!

The machine reproduces human work more consistently and efficiently

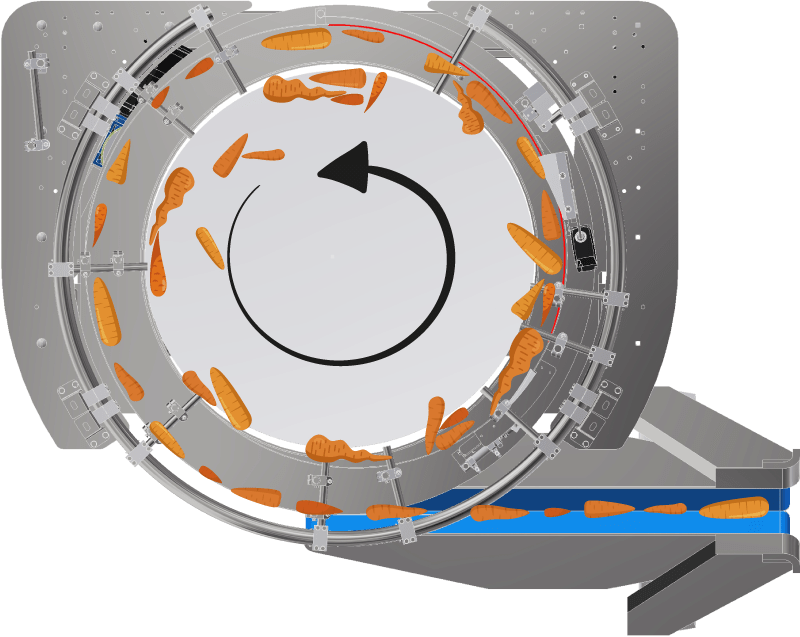

Feeding System

highly increased hourly sorting capacity

A simple and ingenious rotating system aligns carrots of all sizes, smoothly and almost without any duplicates.

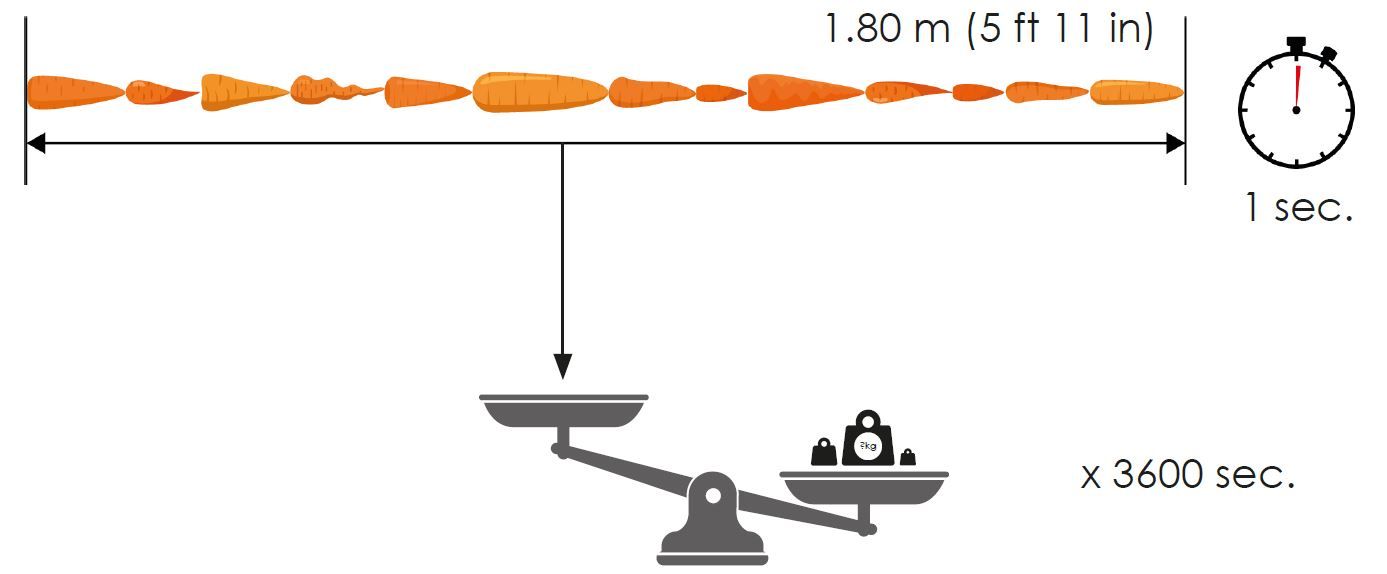

The sorting capacity is at 1.80 m (5 ft 11 in) carrots per second.

The weight of 1.80 m (5 ft 11 in) carrots per second extrapolated to one hour results in the hourly sorting capacity.

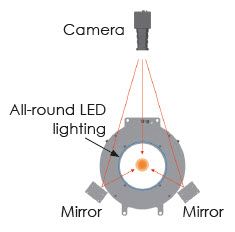

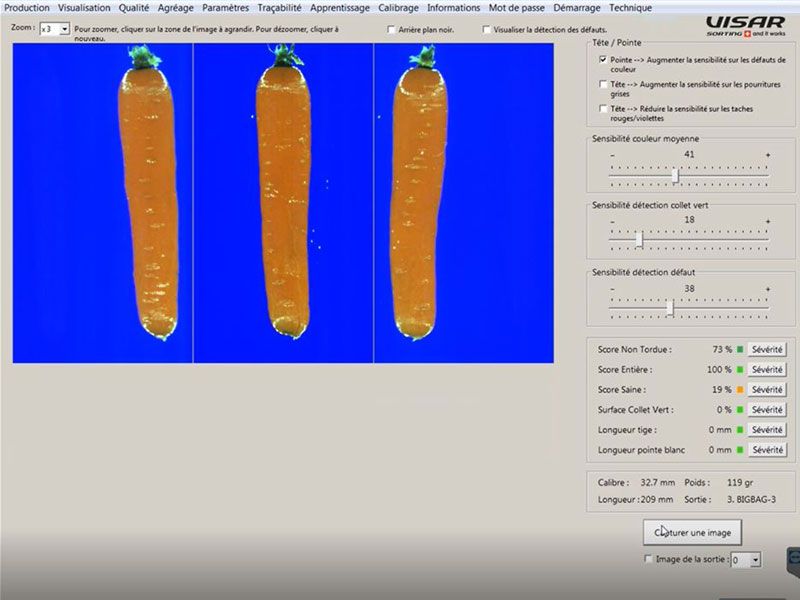

Optical Module

highly precise 360° analysis

Thanks to a mirror system and a very powerful all-round lighting that eliminates shadows, every vegetable is subjected to a perfect 360° analysis. The optical system generates 3 immaculate high-resolution images of each carrot. These can be displayed immediately on the computer screen to check the error detection.

- High-resolution color and infrared camera, error detection from 0.16 mm2

- Calibration accuracy at 1 mm, weight estimate at 1 g

- Visualization of images with display of error detection

- Accepts all shapes of carrots

Calibrates sizes from 10 to 80 mm, length up to 500 mm

Intelligent Software

Acts as a human being

The principle is based on artificial intelligence, which enables the subjective evaluation of the quality, shape and appearance of each carrot and thereby replicates the human appreciation. Combined with other measurable criteria (green collar area, white tip length, stem length), this setting allows the fine-tuning of the sorting accuracy.

- Statistics function

- Complete traceability of each batch

- Perfect integration of the computer and the electrical control built into a waterproof control cabinet

A person evaluates the quality of the vegetables by brecisely visualizing and analyzing the entire surface.

Its assessment is global by combining both quantifiable and subjective information.

Quality criteria may vary based on business needs.

A human being is able to adapt the quality of his sorting, but his constancy decreases with fatigue.

The machine is able to reproduce the work of a human more consistently and more efficiently.

5 Quality levels

The software allows an easy setting of 5 quality

levels (plus waste). The volume and value of the product sold is increased and waste is reduced to a minimum. Thanks to the accuracy of the setting and the unique sorting consistency of the software, a significantly higher yield per batch is achieved.

- Easy setting of 5 quality levels plus waste

- The extra quality product volume is increased

- Waste is reduced to a minimum

- Significantly higher yield per batch

Ejection and Outputs

gently & exactely

Ejection

A nozzle system blows the carrots towards the assigned outputs with extreme precision. The fall is cushioned by soft materials that guarantee a smooth landing.

Outputs

There are 4 to 16 parameterizable outputs available. The products of each exit are passed onto individual conveyor belts. The sorting criteria can easily be adapted to the specific needs of each customer.

Contact us now for more information!

Our dedicated team is at your disposal for questions and information. Do not hesitate to call us.